|

Gotop high-tech co.,ltd

|

eps electric industy packaging mould eps foam pckaging mold

| Price: | 10000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

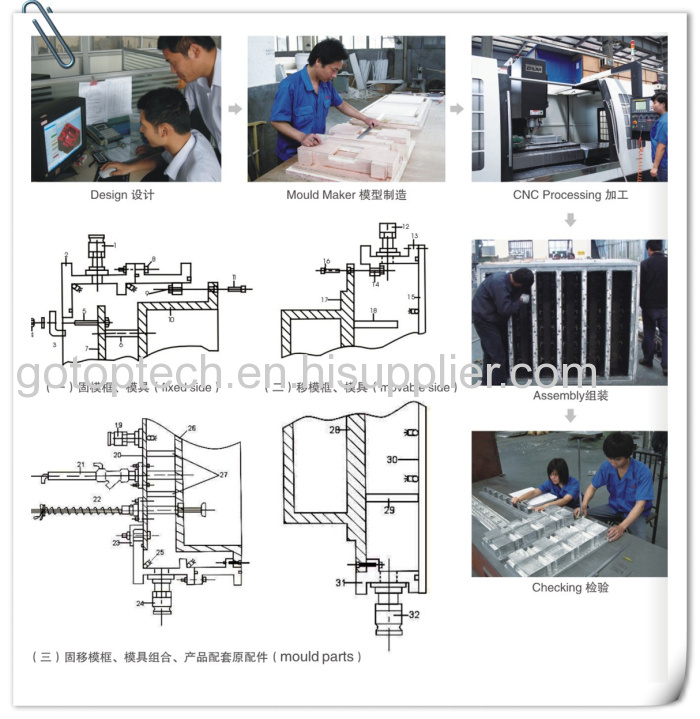

EPS mold making eps packaging box are made by high-quality aluminum alloy, with Teflon coating, assembled by standard steam frame and cooling system.

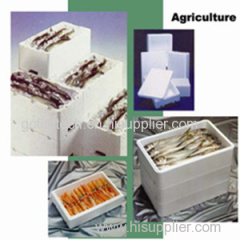

Specializing in the production of various types of EPS foam mold. The company with strong technical force and advanced production and processing equipment, for domestic and foreign users design and manufacture all kinds of foam molds, the main products for the electrical industry, aquaculture, agricultural industry, construction industry, foundry machinery industry etc..

1) Mold dimensions: 1500 x 1200mm

2) Product dimensions: 1050 x 850 x 350mm

3) Connected load: 10.6kW

Max. Product dimension: 1850*1600*350mm,

Steam consumption: (10-13)steam of 1Tmaterial

Various applications in agricultural and elctronic parts packaging. Such as fish box. ICF. Insert, decoration parts. Helmet. Model. Etc.

The EPS shape moulding machine has many improvements compare to the basic type shape molding machine and the features are as follows:

1. Machine structure:

A, All frame are welded by 16/20mm steel plate with high machine legs, greatly improve machines' stronger;

B, High machine legs made by strong "H" type profile. Which is easy for operator to collect products;

2. Filling system: Adopt normal pressure\vacuum and high pressurized filling, hopper controlled by level sensor with double rotation chamber discharge, and 44 filling outlet;

3. Steam system: Adopt balance PID control valve with Germany gauge, greatly improve accurate steam, and reduced consumption;

4. Cooling system: Big vacuum pump with vertical tank, equip with vertical vacuum cooling water spray on the top, steam outlet has air\water separator, all these keep very high efficiency;

5. Drainage system: Increased large inlet and outlet of mould, adopts 8- 1" outlet for steam, keep fast cycle time, 8-2" outlet for drainage system, keep fast drainage; And 6" big drainage pipe controlled by butterfly valve, greatly increased fast steam and fastdrainage operation;

6. Control system:

A, Adopts PLC(Japan Mitsubishi) and touch screen (French Schneider) with easily operation;

B, All electronic components adopts famous brand(Schneider, Omron, Germany gauge), greatly increased stable;

C, The air cooling\steam\de-mould\pressure of filling controlled by long-distance adjustable and balance valve control.

CE certificate, ISO9001:2008

Processing:

Application:

Application: